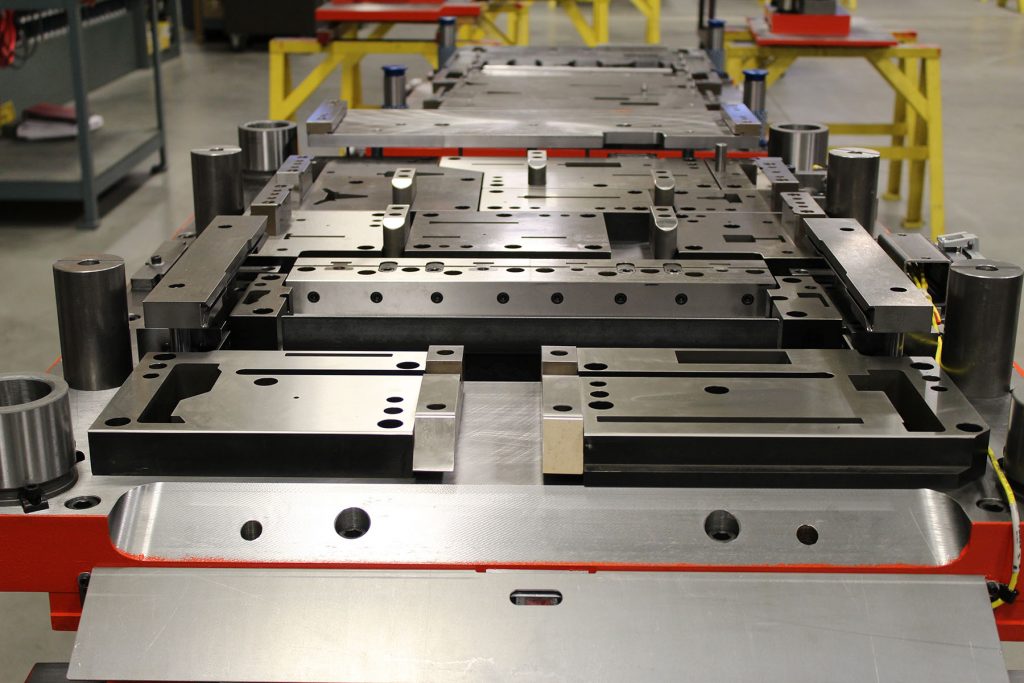

For over 57 years the Tool & Die experts at RTD have been helping to form the future of American manufacturing by designing and constructing the highest of quality metal stamping dies. Our highly skilled journeymen tool & die makers share their years of expertise to assist in the development of the apprentices that are on their own journey to becoming the next generation of experts in building progressive, compound, transfer, and form tooling for our diverse customer base.

The tool room was designed and developed to support the needs of our team by providing the best in class tooling to our discerning client base. At the heart of this venture is a CNC machining cell that was engineered using lean principles. The team that developed the cell focused on the elimination of waste. In addition to the CNC cell, the tool room is supported by several Wire EDMs, and waterjet cutting that can create development blanks as well as speed up the tool machining process.

“Our company has used Reich Tool & Design for much of our Tooling and Design needs for the 14 years I’ve been here. RTD does quality work in a timely manner. I have a lot of confidence in their work and project management. There have been numerous times where they’ve helped us out of a jam by expediting emergency repair components. RTD’s our first choice.”

R.R., Senior Manufacturing Engineer

Appliance Industry

Upon the completion of the tools by the craftsmen in our tool and die assembly area, the tools will be proven out in one of our three try-out presses. Completed first piece samples are verified in our fully equipped Quality Lab which includes the following: Browne & Sharpe CMM, Vision System, and a Faro Arm with Laser Scanner.